Products are always looking attractive when they are packaged in the best way. It might also interest you to know that most time, even if products are gotten for a small amount of money when they’re about to be sold out, the way it’s properly packaged matters a lot. This is basically because, the way the product is packaged will speak volumes of its originality, according to a general mentality. Knowing more about how molded pulp packaging is done, you’ll see that it gives a high assurance of getting your product secured at your door post with no damage. Properties like mugs, cups, doors, or windows made of aluminum that want to be moved to a distant location need Molded Pulp Packaging. This protects the property and keeps them in their space without damaging it. This pulp is produced and can be referred to as molded fiber.

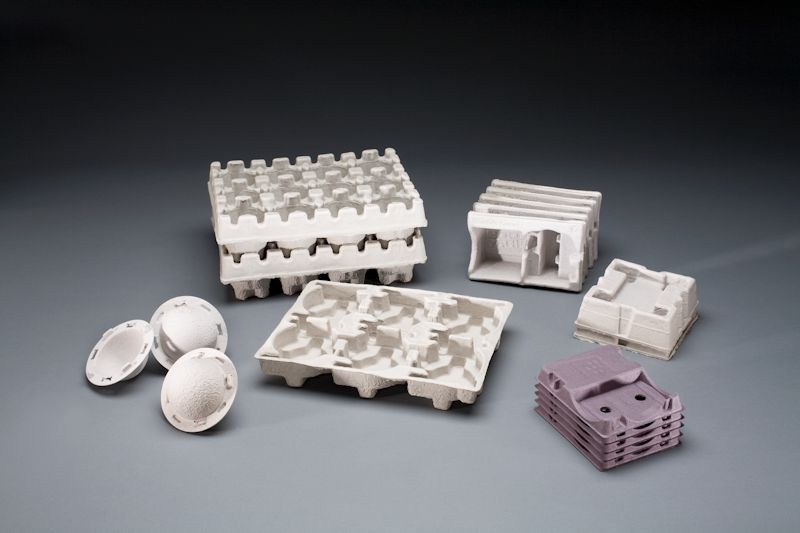

Molded Pulp Packaging is the best for packaging products because it’s not too weighty to add more excess weight to the product. It is made of paper and always in the shape of the product, it wants to be packaged with. Pulp packages are of different shapes, sizes, and colors. The paper, cardboard of cut, and natural fiber used to make this pulp stands to tell the type of color it will express after it’s made. There are several ways in which the pulp packaging method has profited a wide range of the world to a great extent. The environmental impact that this packaging has presented is zero amount of waste in the community, and no water wastage, as all water evaporates into the sky—availability of raw materials in a greater measure and chemical-free processing.

There is a rate of traditional benefits and environmental benefits that pulp packaging offers, but it can not be compared to the low level of benefit that is expressed by the styrofoam means of packaging. Molded pulp packaging presents economic benefits like; getting refined raw materials products to lower rates, all because there was no need to waste in making new plastics or packaging containers. It also helps to form waste faster than needed products, and then shipping these newly formed packaging materials needs a low capital to make it a reality, making it selling out to be more affordable but reliable.