Stainless steel tubeless heat exchangers are vital components in various industrial processes, playing a crucial role in heat transfer applications. To ensure optimal performance and longevity of these heat exchangers, proper maintenance is essential. The maintenance requirements for stainless steel tubeless heat exchanger, cover cleaning procedures, inspection, lubrication, monitoring parameters, and more.

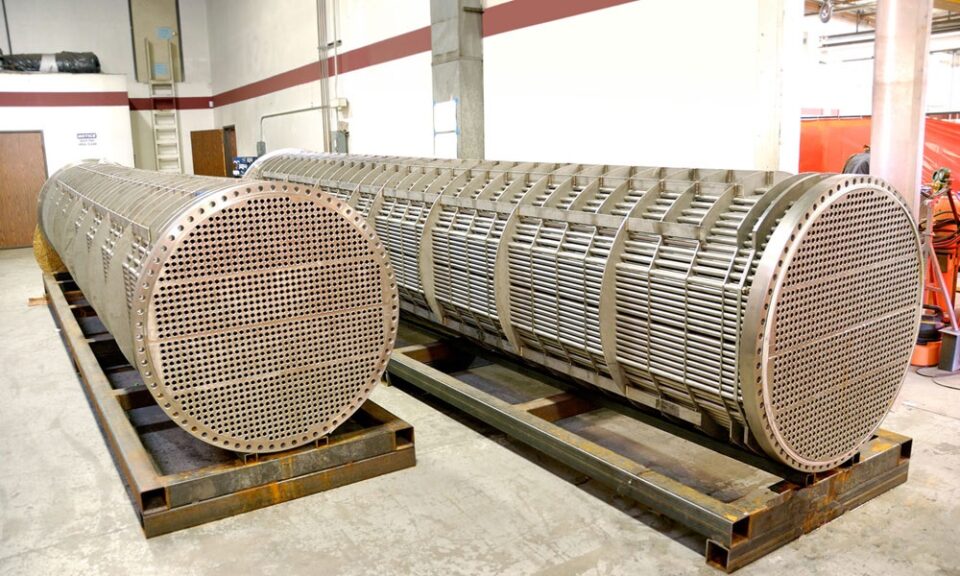

Stainless Steel Tubeless Heat Exchangers

Stainless steel tubeless heat exchangers are commonly used in industries such as food and beverage, pharmaceuticals, petrochemicals, and HVAC systems. They are designed to efficiently transfer heat between two fluids without mixing them. Unlike traditional shell-and-tube heat exchangers, tubeless heat exchangers eliminate the need for gaskets and reduce the risk of leakage, making them a preferred choice in many applications.

Importance of Maintenance

Maintenance plays a critical role in ensuring the efficient operation and longevity of stainless steel tubeless heat exchanger. Regular maintenance not only enhances performance but also minimizes downtime and repair costs. By adhering to a maintenance schedule, operators can prevent issues such as decreased efficiency, corrosion, and mechanical failures.

- Ensuring Efficiency

Regular maintenance helps to keep the heat exchanger operating at peak efficiency, ensuring optimal heat transfer between the fluids. This translates to lower energy consumption and reduced operating costs for the facility.

- Prolonging Lifespan

Proper maintenance extends the lifespan of the heat exchanger, reducing the need for premature replacements. By addressing minor issues early on, maintenance prevents major failures that could result in costly repairs or replacements.

- Regular Cleaning Procedures

Cleaning is a fundamental aspect of heat exchanger maintenance, especially for stainless steel tubeless models. Over time, deposits such as scale, rust, and biological fouling can accumulate on the surfaces, impeding heat transfer and reducing efficiency.

- Removing Deposits

Routine cleaning involves removing deposits from the internal and external surfaces of the heat exchanger. This can be accomplished using mechanical methods such as brushing or chemical cleaning agents designed specifically for stainless steel surfaces.

- Preventing Corrosion

Stainless steel is known for its corrosion resistance, but it’s not entirely immune to corrosion. Regular cleaning helps to prevent corrosion by removing contaminants that could react with the metal surfaces and compromise their integrity.

Lubrication of Moving Parts

Stainless steel tubeless heat exchangers may contain moving parts such as valves, pumps, and actuators that require lubrication to operate smoothly. Regular lubrication prevents friction and wear, ensuring the longevity of these components.

By following a comprehensive maintenance regimen that includes cleaning, inspection, lubrication, and monitoring, operators can maximize performance, minimize downtime, and extend the lifespan of these critical components.